#Parallel Copper Battery Terminals

Explore tagged Tumblr posts

Text

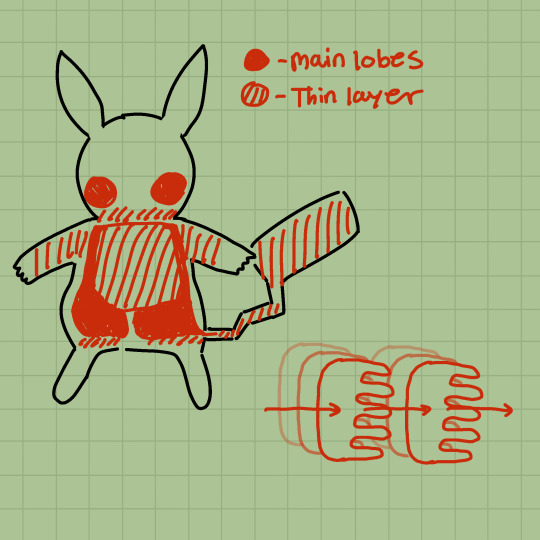

How do Pikachu produce electricity?

(This is a photo of my Pikachu, Eggnog, blending in with a bunch of plushies on my bed. Isn't she cute?)

Electric types are my specialty, so I thought a great way to start off this blog would be to get into the anatomy of electric organs in pokemon! It differs depending on the species, but its pretty conserved among electric mice.

Much of Pikachu's body is made up of two dense electric organs in its body cavity. Most of the mass is in the lower half of the body, separated from the organs by a relatively thick layer of insulating fat. This is why Pikachu are heavier than you might expect for their size! These organs are made of layers of thousands of columns of cells called electrocytes arranged in series, with parallel layers separated by thin insulating tissue to prevent short circuiting. This enables them to efficiently build a high amount of current and voltage very quickly. In the chubbier parts of the arms, tail, and insulated from the organs in the rest of the body cavity are thinner layers of electrocytes to maximize electricity generation.

Interestingly, electrocytes are actually a type of modified muscle cell! Each cell is innervated by a nerve terminal where neurotransmitter release triggers an action potential similar to those in muscle cells and neurons.

The electric organs are beneath the muscle layer and separated by another layer of insulation to prevent seizing during the release of electricity. Insulated channels between the muscle layer allows the produced electricity to move past the muscle and escape through the skin. These channels can be opened and closed to direct electricity to different parts of the body for different moves (think Electro Ball!)

Pikachu fur differs from non-electric type furry pokemon in that it's actually composed of a mixture of several metals (primarily copper and zinc) coated in a thin layer of a protein similar to the chitin found in bug types. In this way, the fur acts more to conduct electricity than to insulate the pokemon against temperature loss. This makes temperature control a challenge for Pikachu, but the thick layers of fat insulation, metabolic heat from electricity production, and social huddling helps keep them warm.

You might've noticed that Pikachu's striking red electric sacs in its cheeks are completely hairless. This helps it directly conduct electricity in smaller amounts, like when communicating. These sacs are also the only electricity-generating organs in its head, and are thoroughly insulated to prevent any misfiring to the brain. This has the side effect of making its cheeks extra stretchy and squishy!

These electric sacs also differ from the main electric organs in that they have specialized battery glands that can store even more electricity. When Pikachu is asleep, they're able to "recharge" these glands similar to the process in rechargeable batteries, except with very minimal efficiency loss over its lifespan.

And there you have it! A basic run down of how Pikachu generates electricity. If you have any questions or comments, please feel free to let me know! And of course, if you have any corrections, please let me know as well! I'm pretty experienced with electric types but I'm also still just a student. :]

72 notes

·

View notes

Text

Joining Forces: The Vital Role of Welding in Battery Production

Whether dealing with square or cylindrical batteries, welding stands as a cornerstone of the manufacturing process. In the intricate dance of lithium-ion battery production, welding techniques are primarily employed in the middle and later stages, where precision and reliability are paramount.

Let's explore some key welding processes that contribute to the creation of safe and efficient batteries:

1. Safeguarding with Explosion-Proof Valve Welding (Safety Vent Welding)

The explosion-proof valve, often called a pressure relief valve, is a critical safety feature. It's a thin-walled component located on the battery's top cover. In the event of excessive internal pressure, this valve is designed to rupture, releasing gas and preventing a catastrophic battery burst.

This valve boasts a clever design, typically involving laser welding two precisely shaped aluminium sheets together. The laser welding process must be meticulously controlled to ensure a reliable seal and consistent rupture pressure. If the weld is too weak or too strong, it can significantly compromise battery safety. Therefore, this process demands extremely precise control over the heat applied.

2. Connecting the Power: Terminal Welding

The battery cover features positive and negative terminals, which serve as the pathways for electrical current. Electrons flow from the active materials within the battery, through foils, tabs, and terminal extensions, ultimately reaching the vehicle's electrical components.

Terminal connections are categorized as internal and external. Internal connections involve welding the battery cell tab to the cover's terminal. External connections involve welding the battery terminal to connecting pieces, forming series or parallel circuits within a battery module.

Typically, the positive terminal is made of aluminium, while the negative terminal is made of copper. A common construction involves riveting followed by full welding. To meet the required tensile strength and conductivity, fibre lasers or composite welding lasers, known for their excellent beam quality and uniform energy distribution, are preferred. These lasers help achieve stable welds in both aluminum-aluminum and copper-copper structures, minimizing spatter and maximizing production yield.

3. Bridging the Gap: Tab Extension Welding

Adapters and flexible connectors are essential components that link the battery cover and the battery cell. These components must withstand high currents, maintain structural integrity, and minimize spatter. Therefore, the welding process must create a sufficiently wide weld while preventing any particles from falling onto the battery cell, which could cause a short circuit. Copper, being a highly reflective material, requires a higher energy density for successful welding.

4. Sealing the Shell: Shell Sealing Welding (Can Sealing Welding)

Power battery shells are typically made of aluminium alloy, with some made of pure aluminium. Stainless steel, particularly 304 stainless steels, is also used due to its excellent laser weldability.

Continuous laser welding of thin-shell lithium-ion batteries significantly boosts efficiency while enhancing appearance and sealing. To achieve even faster welding speeds and a more uniform appearance, many manufacturers are adopting composite welding and annular spot welding, moving away from slower single-fiber welding. In mass production, welding speeds have reached impressive levels, while ensuring weld stability.

5. Securing the Seal: Sealing Nail Welding

Sealing nails, or injection hole caps, come in various forms, often round caps. The welding process must ensure a robust seal capable of withstanding high pressure, free from pinholes, cracks, or explosion points.

As the final step in battery core welding, the yield of sealing pin welding is particularly important. Residual electrolyte can lead to defects like explosion points and pinholes. Minimizing heat input is crucial for suppressing these defects. Laser welding significantly enhances stability and consistency, leading to improved yields.

6. Building Modules and Packs: Module and PACK Welding (Busbar Welding)

A battery module is essentially a combination of lithium-ion cells connected in series and parallel, equipped with individual cell monitoring and management devices. The module's structural design dictates its performance and safety. It must support, secure, and protect the cells while meeting overcurrent requirements, ensuring current uniformity, controlling cell temperature, and providing a means to cut off power in case of severe abnormalities.

Because laser welding copper and aluminium together can create brittle compounds, it is generally used for copper to copper and aluminium to aluminium, in addition to ultrasonic welding. Because copper and aluminium have high laser reflectivity and conduct heat quickly, the connecting piece tends to be thick, requiring higher power lasers.

In Conclusion:

Welding is not merely a joining process in battery production; it's a critical determinant of safety, performance, and longevity. Each welding stage, from the delicate safety vent to the robust module assembly, demands precision and control. The adoption of advanced laser technologies and meticulous process management are essential for achieving high-quality, reliable welds. As battery technology continues to evolve, so too will the welding techniques that underpin its advancement, ensuring safer and more efficient energy storage solutions.

#laser welding#laser welding machine#laser welding machine in India#laser welding equipment#fiber laser welding machine

0 notes

Text

2/0 AWG Copper battery 2pack Electrical Terminals

These copper terminals feature a robust, corrosion-resistant design that ensures long-lasting performance even in harsh environments. Copper’s excellent conductivity helps to reduce heat buildup, preventing energy loss and improving the overall efficiency of the electrical system. The terminals are designed for easy installation, with a secure grip to accommodate larger gauge wires, making them ideal for connecting batteries in parallel or series configurations.

Included in the 2-pack are two terminals, each capable of handling high current loads, making them suitable for both residential and commercial applications. They are designed to accommodate standard cable lug sizes, and their durable construction ensures a firm, stable connection that can withstand vibration and mechanical stress.

Whether you’re upgrading your electrical system or building a new one, the 2/0 AWG Copper Battery Terminals offer the performance, durability, and reliability required for optimal power flow and long-term battery health.

Contact

+𝟭 𝟳𝟳𝟵-𝟳𝟳𝟬-𝟯𝟭𝟬𝟵

1585 Beverly CT, Unit 121, Auror

0 notes

Link

#Brass Battery Connectors#brass parts#Custom Brass Parts#brass components#custom battery connectors#Custom Manufacturing#exporter#Parallel Copper Battery Terminals#battery terminals#battery connectors#USA

0 notes

Text

COPPER CABLE LUGS-ALUMINIUM CABLE LUGS

What exactly are Copper Lugs?Lugs made of copper:

Have you ever wondered what that silver gleaming metal at the end of your cables or between your wires is? It's a Copper Lug, after all. They attach cables to electrical appliances, other cables, surfaces, or mechanisms using Copper Lugs, also known as cable lugs. Copper lugs are commonly seen on the clamps that connect wires to an automotive battery, as well as on the ends of battery jumper cables. Copper lugs are commonly employed when permanent, direct-fastening methods are neither practical nor essential. They are designed to be quickly placed and removed for repairs or maintenance. In order to prevent damage to copper lugs, cables, connectors, and short circuits, they may be covered with a protective coating. Copper lugs are appropriate for heavy gauge power demand or grounding applications. Each copper lug has the option of being crimped or soldered to wire. For an aesthetically pleasing finish, the copper lug has a burr-free look. Depending on the type of lug, one end of the copper lug fits the cable through soldering, welding, or crimping. A bolt, screw, or spring clip is used to secure the other end of the copper lug to a matching termination or connecting point.

Application:The Cable Lug connects a cable to the device while the other end is connected to the connection termination. To ensure a secure connection, the initial end is crimped, soldered, or welded. The second end is held together with a screw or bolt. The application of terminal and

bimetallic lugs

vary as per industry.

Cable lugs come in a variety of sizes, forms, and materials, as well as various configurations. Insulated lugs with various terminals, such as a pin, blade, hook, fork, and ring terminal, are required in the wiring, automation, control panel, and instrumentation industries.

For many connection needs, most devices are connected with copper ring-type lugs. Another form of the lug is the butt and parallel connector. These are used when two cables need to be terminated or linked.

Heat shrinkable, closed-end type, butt type, and PVC insulated are the most popular. Depending on the cable type, copper cable lugs can also be utilized as butts and parallel connectors.

On the off chance that you had any inquiry regarding our "Copper Cable Lugs and Aluminium Cable Lugs" at that point don't hesitate to get in touch with us.

1 note

·

View note

Text

How do solar panels work?

During the last two decades, the contribution of solar energy to the world's total energy supply has increased significantly. Energy from the sun is the most abundant and absolutely free energy available on Earth. Solar photovoltaic systems convert solar energy directly into electrical energy. As sunlight strikes a cell in a panel, the cell converts the light into electricity.

The science behind solar cells

To harness solar energy, we need the help of another element found abundantly on Earth's sands. To be used in a solar cell, and needs to be converted into 99.999% pure silicon crystals. To achieve this the sand has to undergo a complex purification.

Sand + carbon → crude silicon

Raw silicon turns into a gaseous silicon compound. It is then combined with hydrogen to obtain very pure silicon. These silicon ingots are then shaped and turned into very thin pieces called silicon wafers. The silicon wafer is the heart of the PV cell.

Solar cell manufacturing

As we know we use semiconductors (silicon) to make solar cells. Here we use two types of silicon semiconductors namely p-type and n-type. An n-type material with a thickness of 0.3 μm was placed on top of the cell and a p-type material with a thickness of 300 μm was placed on the bottom of the cell. N-type material is thinner than p-type material because it can easily enter the cell when sunlight hits it. There is some metal finger on the top of the N-type material. Connecting metal fingers lead to a wire that acts as the negative terminal. Above the metal fingers is a bus bar. Underneath the p-type material is a back contact made of copper through which we pull out the positive wire. Therefore, the solar cell works as a battery. These solar cells are connected in series/parallel and form a solar panel.

Solar panel structure

Solar panels have different layers, and one of them is the cell layer. The upper negative side of the solar cell is connected to the lower positive side of the next solar cell through copper strips. It forms a series of cells When a series of cells are connected in parallel with another series of cells it forms a panel. A single cell is 0.5v. A combination of series-parallel cells increases the voltage and current values to usage limits.

Layers of EVA sheeting on both sides of the cells protect them from shock, vibration, and moisture. There is an anti-reflection coating (tempered glass) that prevents radiation from escaping or heating the cell.

How does this work?

Sunlight falling on Earth is actually bundles of photons or small bundles of energy. Each photon has a finite amount of energy. To generate electricity, photons must be absorbed by solar cells. Photons in sunlight falling on the front of the solar cell are absorbed by the semiconductor material.

P-type materials have few holes and N-type materials have fewer electrons. These electrons are free electrons. When we connect P and N-type materials there is a junction between them called a depletion layer. Since the electrons in the N material are empty, they come through the depletion layer to the P side and fill the holes in the P side. Therefore, there are no free electrons and holes in the depletion layer. Due to electron migration, the n-side boundary becomes slightly positive and the p-side becomes negatively charged.

When light hits the N region of the PV cell it penetrates and reaches the depletion region. This photon energy is sufficient to generate electron-hole pairs in the depletion region. The electric field in the depletion region drives electrons and holes out of the depletion region. The concentration of electrons in the N region and holes in the P region become so high that a potential difference develops between them. As soon as we add any load between these regions, electrons will start flowing through the load. After the electron completes its path, it will reconnect with the holes in the p region.

Thus, a solar cell continuously delivers a direct current. Therefore, a solar cell on which sunlight falls can directly drive DC electrical equipment. But, the amount of electricity generated is proportional to the amount of light incident. Therefore, the amount of electricity generated throughout the day is not constant.

How solar panel efficiency matters in production

A solar cell converts some of the light energy falling on it into electrical energy. Thus, even a PV module converts only a fraction of the total light falling on it into electrical energy. The ratio of the electrical energy produced to the input light energy is called the efficiency of the PV module. The efficiency of the module basically depends on the solar cells used and the method used to interconnect them. In a module, cells can be interconnected in series or parallel connections. Once a module is assembled, its efficiency value is fixed and generally does not change.

The efficiency of a module is given as the maximum power or peak power that the module can produce for a given input of solar radiation. For a given input power pin, the value of the output power is directly determined by the efficiency of the module and the value of the module area. Therefore, a module with higher efficiency values will produce more power because efficiency is directly proportional to maximum power. The output will be higher because the efficiency of the module is higher.

0 notes

Text

How to Select the Right LiFePO4 Battery Busbars?

LiFePO4 battery busbars are an important accessory and an option that cannot be ignored when you DIY a LiFePO4 battery pack. Proper battery busbars are critical to improving the performance of the entire battery pack.

LiFePO4 Battery Busbars & Thick Gauge Cable, who’s the best?

First, we need to know that to connect your LiFePO4 battery, you have two options: battery busbars or thick gauge cable. Battery busbars are circuit-connecting metal bars that are used for short-distance connections, support high-current power distribution, and are optimized for current requirements and performance specifications, which can effectively handle high current and heat dissipation. Battery busbars can be made in a variety of shapes, generally in the shape of flat bars, but also in the shape of solid rods and hollow tubes. Among them, the flat or hollow-shaped busbars are usually suitable for high current applications. The thick gauge cable can be simply understood as a thickened wire, which can provide the function of circuit connection for your LiFePO4 battery.

We generally use battery busbars to connect our cells, because busbars are more flexible, safer, and relatively low-cost, so they are the most common and popular. But some people will choose thick gauge cable for some reason.

What material are LiFePO4 Battery Busbars made of?

There are two main types of LiFePO4 battery busbars, copper busbars, and brass busbars. Both materials have very good electrical conductivity and are very suitable for battery busbars.

Copper has very high electrical conductivity, low electrical resistance, and high tensile strength. This has led many to believe that copper is the conductor of choice for electrical circuits. However, copper busbars generally do not expose copper directly to the air but are plated with a non-corrosive material on the surface to prevent copper oxidation.

Brass is a mixture of copper and other metals or substances. The electrical conductivity is relatively good, and it is stronger and less ductile. Brass busbars are relatively modest.

How to Select the LiFePO4 Battery Busbars?

First, you need to decide which type of LiFePO4 battery busbars to use based on your circuit system. If the capacity of the battery pack is large and the requirements for electrical conductivity are relatively high, then copper busbars are the best choice.

Then you need to choose battery busbars according to the size of each cell. There are three most important factors to consider: the length, width, and thickness of the busbars.

First of all, it is necessary to determine the connection method of the cells in the circuit system. The lengths required for series and parallel are different, and the lengths required for bold or straight methods are also different. The length of the busbars must be appropriate, because too long busbars may cause some unexpected risks. In addition, the width needs to be wide enough, and the secret to maximizing battery pack performance is maximizing the contact area between the cell terminals and the busbars. And the thickness needs to be enough to support the current flow, too thin busbars can not play the best conductivity. It is worth mentioning that busbars of suitable width, length, and thickness can better match the performance of the battery pack, while busbars with excess performance are not very recommended, because busbars that exceed the internal performance of the battery pack will only cause waste.

Calculating measurements for the length, width and thickness of the battery busbars required are actually not difficult.

Length, you need to measure the distance between the two cell terminals, and you need to reserve a little space – too compact busbars may damage the cell terminals.

Width, you need to measure the width of the cell terminal, generally choose 3/4 width of the cell terminal as the reference width of the busbars, so as to match the cell stud.

Thickness, this parameter means that the current, resistance, and ampacity of the battery pack must be weighed to determine how thick the busbars are needed to support the electrical load. Among them, resistance is the most important parameter, and the calculation formula of resistance is resistance (R) = resistance of the material (p) * length of material (l) / cross-sectional area of material (A).

Finally, remember that about a week after the battery pack is installed, it is necessary to double-check that all battery terminals and the busbars are still tightened, because once loose, there is a risk of causing high resistance connections, which can reduce the performance of the battery pack. At the same time, there are also some unsafe factors.

Summary

The correct selection and installation of LiFePO4 battery busbars determine the power output of your battery pack. Although choosing busbars may seem complicated, don’t worry too much. At present, most of the LiFePO4 battery wholesalers will match the most suitable busbars for the LiFePO4 batteries they sell, which can perfectly solve the related problems. There are only a few cases where you will need to make battery busbars yourself.

Origin: https://batteryfinds.com/how-to-select-the-right-lifepo4-battery-busbars/

0 notes

Text

Understanding the Uses of Cable Lugs & Connectors c

Cable lugs are electrical device components that connect the cable to the device terminals that simplify personnel assembly, maintenance, and repair processes. During the need for a permanent connection, we use these cable lugs. However, a direct link is unbelievable to achieve. Made from high-grade electrolytic copper (ETP Grade), these cable lugs are available for purchase in different diameters wire sizes and mounting holes. The terminals are CSA & UL approved and have corrosion-resistant tin plating.

Cable lugs make installing, repairing, and maintaining electrical devices and cables simple. They help connect more than two cables fuse sockets, load switches, and electrical equipment, and link two wires.

Different Characteristics of Cable Lugs

In the case of cable lugs, these materials have to go through a mechanical pull-out test & electrical durability to ensure performance. Cable lugs that have a bell mouth shape allow smooth insertion in the case of conductors.

Cable lugs undergo high current tests at 250 degrees Celsius, and high-quality materials offer advantages such as higher loading capacity, optimal conductivity, and heightened safety.

Also, the dimensions of a Copper tube are customized to fit a specific Sq.mm of cable.

Importance of Cable Lugs

Cable lugs help repair, maintain, and install cables and electrical devices.

Other lugs, Butt, and parallel connectors join and terminate two cables. Some commonly used Butt and parallel connections are PVC insulated, butt type, heat shrinkable, and closed-end. These Butt and parallel connections come in a variety of sizes and shapes. Another type, Copper ring-type lugs, are also helpful for many connecting reasons, such as connecting several gadgets with cables.

Lugs have an important use in the wire and electrical sector. They get tested for strength before applying them in a heavy-duty machine. It is critical to select the correct lugs based on their intended use, as the strength and design of lugs are essential in numerous applications. Most insulated lugs consist of blade terminals, pin terminals, fork terminals, hook terminals, and ring terminals used in the control panel, wire, and automation industries and instrumentation companies. A cable lug that has a ring-type shape is used for multiple connections. These lugs help in creating links between cables and different gadgets. That is why the cable lugs manufacturers in India tend to provide the best quality materials for their cable lugs.

Usually, lugs help to attach distribution boxes and transformers to cables. Numerous industrial segments use it, from Transformers, motors, generators, batteries to distribution boards and many more.

Have any queries, you can talk to our industry professional by visiting our contact us section.

About the Company:

Axis is the leading Indian Manufacturer & Exporter of a wide range of Electrical Components used in Electrical Installations and in the Equipment Building industry. Their main customer base consists of Distributors/Wholesalers of Electrical Products, Electrical Contractors & Installers, Equipment Manufacturers, Maintenance Companies and Government Authorities.

0 notes

Photo

High quality battery packs with a modular set-up

This photo shows the test installation for a high-performance quality pack using the ELERIX 50AH cells. The two cells are installed in parallel to reach the 100AH capacity. The massive copper terminal plates make sure there will be a minimal loss of the energy during the peak discharge rates.

This pack is designed to be discharged at up to 3C continually providing some 300Amp of power.

As repeatedly explained, this is an example of a fully modular and fully serviceable battery pack. Any of the cells can be replaced if needed. Also, in case of a change of the specification, this type of pack can be disassembled and reconfigured into another voltage or capacity.

Read additional comments related to this topic in an article here:

The factory manufactured packs – Say No! to the battery black-boxes

0 notes

Text

Sodium (18Ah Cells) 4S 5P Busbars and Hardware

Sodium-ion batteries, using 18Ah cells in a 4S 5P configuration, are gaining attention as an alternative to traditional lithium-ion technology due to their lower cost and environmental benefits. In a 4S 5P setup, four cells are connected in series (4S) to provide the required voltage, while five cells are connected in parallel (5P) to achieve a total capacity of 90Ah. This configuration is ideal for applications requiring significant energy storage, such as large-scale energy systems and electric vehicles.

The busbars used in this configuration are essential for ensuring efficient power distribution between the cells. Made from high-conductivity materials like copper or aluminum, these busbars are designed to handle the high currents generated by the 90Ah battery pack while minimizing energy losses and heat generation. Proper design is crucial for maintaining system stability and preventing potential failures.

In addition to the busbars, hardware components such as connectors, terminals, and insulation materials play an integral role in the battery's performance. These components ensure secure connections between cells and help prevent issues like short circuits, overheating, or voltage imbalances.

As the demand for sustainable energy storage solutions grows, the 4S 5P sodium-ion battery configuration, along with robust busbars and hardware, offers a reliable and cost-effective solution for powering everything from renewable energy storage to electric vehicles.

Contact

+𝟭 𝟳𝟳𝟵-𝟳𝟳𝟬-𝟯𝟭𝟬𝟵

1585 Beverly CT, Unit 121, Auror

0 notes

Text

How solar battery work

With the global energy shortage, solar energy has been vigorously developed as a new type of energy. Among them, solar batterys are the most used in our lives. Solar batterys are mainly based on semiconductor materials. Photoelectric materials are used to absorb light energy and then undergo photoelectric conversion to make it generate current. What is the working principle of solar battery?

In the past, from an electrical point of view, the silicon we used was all neutral. The excess electrons are neutralized by the excess protons in the phosphorus. The missing electrons (holes) are neutralized by the missing protons in boron. When holes and electrons are mixed at the junction of N-type silicon and P-type silicon, neutrality is destroyed. Will all free electrons fill all holes? will not. If so, then the whole preparation is meaningless. However, at the junction, they do mix to form a barrier, making it increasingly difficult for electrons on the N side to reach the P side. Eventually an equilibrium state will be reached, so that we have an electric field separating the two sides.

This electric field is equivalent to a diode, allowing (or even pushing) electrons to flow from the P side to the N side, not the other way around. It is like a mountain-electrons can easily slide down the hill (to the N side), but cannot climb up (to the P side).

In this way, we get an electric field that acts as a diode, in which electrons can only move in one direction. Let's take a look at what happens when sunlight hits the battery.

When light hits a solar battery in the form of photons, its energy causes electron-hole pairs to be released.

Each photon with enough energy usually releases exactly one electron, thereby creating a free hole. If this occurs close enough to the electric field, or free electrons and free holes are just within its influence, the electric field will send electrons to the N side and holes to the P side. This will cause the electrical neutrality to be further destroyed. If we provide an external current path, electrons will pass through the path and flow to their original side (P side), where they merge with the holes sent by the electric field and flow in the process. In doing work. The flow of electrons provides current, and the electric field of the battery produces voltage. With current and voltage, we have power, which is the product of the two.

How much sunlight energy can our photovoltaic cells absorb? Unfortunately, the absorption rate of the solar energy of the simple battery introduced here is at most about 25%, and the usual absorption rate is 15% or lower. Why is the absorption rate so low?

Visible light is only part of the electromagnetic spectrum. Electromagnetic radiation is not single-frequency—it consists of a series of different wavelengths (and thus a series of energy levels). (For a detailed introduction to the electromagnetic spectrum, please refer to the basic principles of special relativity.)

Light can be divided into different wavelengths, and we can see this through the rainbow. Because the photon energy range of the light hitting the battery is very wide, some photons do not have enough energy to form electron-hole pairs. They just pass through the battery, as if the battery is transparent. But the energy of some other photons is very strong. Only when a certain amount of energy is reached-in electron volts (eV), determined by the battery material (about 1.1 eV for crystalline silicon)-can electrons escape. We call this energy value the band gap energy of the material. If the energy of the photon is more than the required energy, the excess energy will be lost (unless the energy of the photon is twice the required energy and multiple sets of electron-hole pairs can be created, but this effect is not important). These two effects alone will cause about 70% of the radiant energy loss in the battery.

Why don't we choose a material with a very low band gap in order to use more photons? Unfortunately, the band gap also determines the electric field strength (voltage). If the band gap is too low, while increasing the current (by absorbing more electrons), a certain amount of voltage will be lost. Remember, power is the product of voltage and current. The optimal band gap energy must be able to balance these two effects. For a battery made of a single material, this value is approximately 1.4 electron volts.

We have other energy losses. Electrons must flow from one side of the battery to the other through an external circuit. We can plate a layer of metal on the bottom of the battery to ensure good conductivity. But if we completely plate the top of the battery with metal, the photons will not be able to pass through the opaque conductor, which will lose all current (in some batteries, only the upper surface is used instead of transparent conductors in all locations). If we only set contacts on both sides of the battery, the electrons need to travel a long distance (for electrons) to reach the contact point. You know, silicon is a semiconductor, and its performance in transmitting current is not as good as metal. Its internal resistance (called series resistance) is quite high, and high resistance means high loss. In order to minimize these losses, the battery is covered with a metal contact net, which can shorten the distance the electrons move while covering only a small part of the battery surface. Even so, some photons will be blocked by the grid, and the grid cannot be too small, otherwise its own resistance will be too high.

Before actually using the battery, there are several other steps. Silicon is a shiny material, which means it has good reflective properties. The reflected photons cannot be used by the battery. For this reason, using an anti-reflective coating on the top of the battery can reduce the reflection loss to less than 5%.

The last step is to install the glass cover to separate the battery from the components to protect the battery. Photovoltaic modules are composed of multiple batteries (usually 36) in series and parallel to provide usable voltage and current levels. These batteries are placed in a sturdy frame with positive and negative terminals led out at the rear, and a glass cover Seal the board.

Monocrystalline silicon is not the only material used in photovoltaic cells. Polycrystalline silicon is also used in battery materials. Although the cells produced in this way are not as efficient as monocrystalline silicon cells, they can reduce costs. In addition, amorphous silicon without a crystalline structure is also used, which is also to reduce costs. Other materials used include gallium arsenide, indium copper selenide and cadmium telluride. Because different materials have different band gaps, they seem to be "tuned" to photons of different wavelengths or different energies. One way to improve efficiency is to use two or more layers of different materials with different band gaps. Materials with higher band gaps are placed on the surface and absorb higher-energy photons; materials with lower band gaps are placed below and absorb lower-energy photons. This technology can greatly improve efficiency. Such batteries are called multi-junction batteries, and they can have multiple electric fields.

0 notes

Photo

Custom electrical system power station. Made out of an old Oscillograph, houses all the switches for my lights, and my battery charger/inverter and also works as a cute lamp. I’ve been watching a lot of Star Trek, I like old industrial things and living off-grid with my own custom designed electrical system means I can get creative. This is where I’d suggest you stop reading if you aren’t interested in me nerding out ❤️. 12V system, with 1 inclined fused wire coming from 3 batteries in parallel. Keeps my terminals on my batteries all nice and tidy. That main wire comes up to a “bud”, basically 2 pieces of wood with copper wire I stripped, to act kind of like 2 giant terminals. (This parts sloppy, but it’ll do for now, and it’s safe. The switches are functional and control my lighting (12V) my inverter (if I use it), aux power outputs like cigarette lighters for USB charging. I also installed a 12V LED Edison bulb in there, with a pull string switch, it shines light into the cabin and makes for a lovely nightlight. It also helps me work on seeing what I’m doing whilst working in the box! Houses my solar chargers, extra redundant fuse relays and looks cute as heck. I’m just waiting on sourcing some dimmers, unfortunately LED dimmers don’t work for my lights unless their 12V led dimmer switches, so I need a PWM module dimmer... I can keep going but I won’t. Thanks for reading ❤️ (at Dawson, Yukon Territory) https://www.instagram.com/p/CHtWvbmnoY1/?igshid=n8u3arhdko4i

0 notes

Text

The 5 Best Car Led Lights Interior: Installation Guide

Source: louisy.store

Guide to car led lights. Impress your friends and add some fun and excitement to your car by adding interior led lights.

Adding lead lights is a good way to make your car stand out from all the others. Although there’s no good car led light “kit” out on the internet right now, everything you need is here on this site!

In this article, we’ll show you exactly how to install led lights in your car.

Best Interior Car Led Lights

These best car led lights are the best to put inside your car. They are compact and easy to place anywhere that it is needed.

1. Govee Interior Car Lights strips

Govee Interior Car Lights, Car LED Strip Light Upgrade Two-Line Design Waterproof 4pcs 48 LED APP Controller Lighting Kits, Multi DIY Color Music Under Dash Car Lighting with Car Charger, DC 12V

By: Govee

Check the Price >

2. LivTee 12V Car LED Light Interior Strip

LivTee 12V Car LED Strip Light, 4pcs 48 LED Multicolor Music Car Interior Lights Under Dash Lighting Waterproof Kit with Sound Active Function and Wireless Remote Control, Car Charger Included

By: LivTee

Check the Price >

3. KORJO Car Underglow Lights

KORJO Car Underglow Lights, 6 Pcs Bluetooth Led Strip Lights with Dream Color Chasing, APP Control 12V 300 LEDs Underbody Lights, Waterproof Underglow Led Light Kit for Cars, Trucks, Boats

By: KORJO

Check the Price >

4. CHUSSTANG Interior Car LED Strip Lights

CHUSSTANG Interior Car Lights, 48 LEDs 4pcs Car LED Strip Lights Bluetooth App Control Lighting Kits and Control Box Music with Car Charger Waterproof Sound Active Function for SmartPhone

By: Chusstang

Check the Price >

5. CT CAPETRONIX Interior Car Lights, Car led strip lights interior

CT CAPETRONIX Interior Car Lights, Car led strip lights interior with APP and IR Remote, Upgrade 2-in-1 4pcs Waterproof RGB 48 LEDs Music Car LED Lights Under Dash Lighting Kit with Car Charger DC 12V

By: Ct Capetronix

Check the Price >

Car Led Lights Installation Guide

You can hack the led lights above by splicing the wires and connecting multiple led lights in parallel and then mounting them in your car where they are needed.

You are going to have to be creative when figuring out how to mount them, but once you do the inside of your car will look amazing!

NOTE: Disconnect battery

Be sure to disconnect the battery when doing any electrical work. This will save you from burning out any fuses or other important electrical components.

Here is a step by step guide to installing your led lights using the type listed above.

You are going to need 4 to 6 of these led lights to get good coverage of the whole interior.

Minimum Supplies

These are the things that you will absolutely need to complete this project.

1. led lights 3. Extra electrical wiring 4. Wire cutters/Splicers 5. Sandpaper

And other supplies needed based on how you decide to mount your led lights.

Step 1: Mounting Your led lights

Overhead:

It’s best to first figure out where you will put your led lights. I found that putting them on the edge of the roof is the best and easiest way to go.

You can hold them in place with a small metal plate or some other way that looks cleaner. Four of them mounted overhead above each door/seat will give you good coverage.

The picture on the right shows how I did it. You should figure out where to mount the led lights before you do any wiring so that you can plan exactly where the wires will go and how long they would have to be.

Underdash:

You can also mount your led lights under the dash, one on each passenger and driver side so that they will illuminate your legs.

Again you will have to be creative and figure out how to best mount them according to your vehicle. I used duct tape here to secure the led light with metal support behind the glovebox.

Switch placement:

Place your switch somewhere convenient where you can reach it while driving.

Avoid drilling too many holes in your dash panels.

I drilled a hole in the panel under the dash so that I could reach it yet it’s still out of the way.

Step 2. Wiring

Once you have mounted all of your led lights, its time to install all the wiring.

The lights should be connected according to the wiring diagram to the right.

NOTE: Sand Contacts

When splicing the wires, make sure to sand the copper a bit with sandpaper to ensure good electrical contact.

NOTE: Check Polarity

The neon lights must be wired in a specific direction (there is a positive and negative wire).

If you get the polarity wrong then the lights won’t turn on. On the right, you can see that each wire is marked according to its polarity.

The negative wire has long gray boxes on it and should be connected to the ground.

The positive wire has little writing on it and should be connected to the positive. Be sure to test which one is which just to make sure.

Battery Connection:

Connect a wire to the positive battery terminal clip. Find a hole in the firewall that leads to the inside of your vehicle.

You can run the wire through the firewall so that it comes out under the dash.

Hiding the wires:

Try to run the wires from the led lights under the plastic paneling and under the dash or under the carpet to where your switch is.

Connecting to Ground:

Find a screw or a bolt under the dash that screws into the frame of the car. This will be your Ground. You can connect all of your negative wires to it.

Step 3. Flip on your led lights!

Clean everything up and you are ready to go! The led lights will look amazing at night while you are cruising around.

Any white or neon colors will light up brightly. Keep in mind that people will probably be able to see inside your car so if you don’t want anyone to see what you are doing then be sure to switch them off.

Enjoy!

from WordPress https://www.bestcarvacuums.com/best-car-led-lights-interior/

0 notes

Text

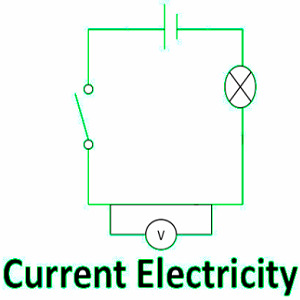

300+ TOP CURRENT ELECTRICITY Multiple Choice Questions and Answers

CURRENT ELECTRICITY Multiple Choice Questions :-

1. The S.I. unit of power is (a) Henry (b) coulomb (c) watt (d) watt-hour Ans: c 2. Electric pressure is also called (a) resistance (b) power (c) voltage (d) energy Ans: c 3. The substances which have a large number of free electrons and offer a low resistance are called (a) insulators (b) inductors (c) semi-conductors (d) conductors Ans: d 4. Out of the following which is not a poor conductor ? (a) Cast iron (b) Copper (c) Carbon (d) Tungsten Ans: b 5. Out of the following which is an insulating material ? (a) Copper (b) Gold (c) Silver (d) Paper Ans: d

CURRENT ELECTRICITY MCQs 6. The property of a conductor due to which it passes current is called (a) resistance (b) reluctance (c) conductance (d) inductance Ans: c 7. Conductance is reciprocal of (a) resistance (b) inductance (c) reluctance (d) capacitance Ans: a 8. The resistance of a conductor varies inversely as (a) length (6) area of cross-section (c) temperature (d) resistivity Ans: b 9. With rise in temperature the resistance of pure metals (a) increases (b) decreases (c) first increases and then decreases (d) remains constant Ans: a 10. With rise in temperature the resistance of semi-conductors (a) decreases (b) increases (c) first increases and then decreases (d) remains constant Ans: a 11. The resistance of a copper wire 200 m long is 21 Q. If its thickness (diameter) is 0.44 mm, its specific resistance is around (a) 1.2 x 10~8 Q-m (b) 1.4 x 10~8 Q-m (c) 1.6 x 10""8 Q-m (d) 1.8 x 10"8 Q-m Ans: c 12. Three resistances of 10 ohms, 15 ohms and 30 ohms are connected in parallel. The total resistance of the combination is (a) 5 ohms (b) 10 ohms (c) 15 ohms (d) 55 ohms Ans: 13. An instrument which detects electric current is known as (a) voltmeter (b) rheostat (c) wattmeter (d) galvanometer Ans: d 14. In a circuit a 33 Q resistor carries a current of 2 A. The voltage across the resistor is (a) 33 V (b) 66 v (c) 80 V (d) 132 V Ans: b 15. A light bulb draws 300 mA when the voltage across it is 240 V. The resistance of the light bulb is (a) 400 Q (b) 600 Q (c) 800 Q (d) 1000 Q Ans: c 16. The resistance of a parallel circuit consisting of two branches is 12 ohms. If the resistance of one branch is 18 ohms, what is the resistance of the other ? (a) 18 Q (b) 36 Q (c) 48 Q (d) 64 Q Ans: b 17. Four wires of same material, the same cross-sectional area and the same length when connected in parallel give a resistance of 0.25 Q. If the same four wires are connected is series the effective resistance will be (a) 1 Q (b) 2 Q (c) 3 Q (d) 4 Q Ans: d 18. A current of 16 amperes divides between two branches in parallel of resistances 8 ohms and 12 ohms respectively. The current in each branch is (a) 6.4 A, 6.9 A (b) 6.4 A, 9.6 A (c) 4.6 A, 6.9 A (d) 4.6 A, 9.6 A Ans: b 19. Current velocity through a copper conductor is (a) the same as propagation velocity of electric energy (b) independent of current strength (c) of the order of a few ^.s/m (d) nearly 3 x 108 m/s Ans: c 20. Which of the following material has nearly zero temperature co-efficient of resistance? (a) Manganin (b) Porcelain (c) Carbon (d) Copper Ans: a 21. You have to replace 1500 Q resistor in radio. You have no 1500 Q resistor but have several 1000 Q ones which you would connect (a) two in parallel (b) two in parallel and one in series (c) three in parallel (d) three in series Ans: b 22. Two resistors are said to be connected in series when (a) same current passes in turn through both (b) both carry the same value of current (c) total current equals the sum of branch currents (d) sum of IR drops equals the applied e.m.f. Ans: a 23. Which of the following statement is true both for a series and a parallel D.C. circuit? (a) Elements have individual currents (b) Currents are additive (c) Voltages are additive (d) Power are additive Ans: d 24. Which of the following materials has a negative temperature co-efficient of resistance? (a) Copper (b) Aluminum (c) Carbon (d) Brass Ans: c 25. Ohm's law is not applicable to (a) vacuum tubes (b) carbon resistors (c) high voltage circuits (d) circuits with low current densities Ans: a 26. Which is the best conductor of electricity ? (a) Iron (b) Silver (c) Copper (d) Carbon Ans: b 27. For which of the following 'ampere second' could be the unit ? (a) Reluctance (b) Charge (c) Power (d) Energy Ans: b 28. All of the following are equivalent to watt except (a) (amperes) ohm (b) joules/sec. (c) amperes x volts (d) amperes/volt Ans: d 29. A resistance having rating 10 ohms, 10 W is likely to be a (a) metallic resistor (b) carbon resistor (c) wire wound resistor (d) variable resistor Ans: c 30. Which one of the following does not have negative temperature co-efficient ? (a) Aluminium (b) Paper (c) Rubber (d) Mica Ans: a 31. Varistors are (a) insulators (6) non-linear resistors (c) carbon resistors (d) resistors with zero temperature coefficient Ans: b 32. Insulating materials have the function of (a) preventing a short circuit between conducting wires (b) preventing an open circuit between the voltage source and the load (c) conducting very large currents (d) storing very high currents Ans: b 33. The rating of a fuse wire is always expressed in (a) ampere-hours (b) ampere-volts (c) kWh (d) amperes Ans: d 34. The minimum charge on an ion is (a) equal to the atomic number of the atom (b) equal to the charge of an electron (c) equal to the charge of the number of electrons in an atom (#) zero Ans: b 35. In a series circuit with unequal resistances (a) the highest resistance has the most of the current through it (b) the lowest resistance has the highest voltage drop (c) the lowest resistance has the highest current (d) the highest resistance has the highest voltage drop Ans: d 36. The filament of an electric bulb is made of (a) carbon (b) aluminium (c) tungsten (d) nickel Ans: c 37. A 3 Q resistor having 2 A current will dissipate the power of (a) 2 watts (b) 4 watts (c) 6 watts (d) 8 watts Ans: c 38. Which of the following statement is true? (a) A galvanometer with low resistance in parallel is a voltmeter (b) A galvanometer with high resistance in parallel is a voltmeter (c) A galvanometer with low resistance in series is an ammeter (d) A galvanometer with high resistance in series is an ammeter Ans: c 39. The resistance of a few meters of wire conductor in closed electrical circuit is (a) practically zero (b) low (c) high (d) very high Ans: a 40. If a parallel circuit is opened in the main line, the current (a) increases in the branch of the lowest resistance (b) increases in each branch (c) is zero in all branches (d) is zero in the highest resistive branch Ans: c 41. If a wire conductor of 0.2 ohm resistance is doubled in length, its resistance becomes (a) 0.4 ohm (b) 0.6 ohm (c) 0.8 ohm (d) 1.0 ohm Ans: a 42. Three 60 W bulbs are in parallel across the 60 V power line. If one bulb burns open (a) there will be heavy current in the main line (b) rest of the two bulbs will not light (c) all three bulbs will light (d) the other two bulbs will light Ans: d 43. The four bulbs of 40 W each are connected in series swift a battery across them, which of the following statement is true ? (a) The current through each bulb in same (b) The voltage across each bulb is not same (c) The power dissipation in each bulb is not same (d) None of the above Ans: a 44. Two resistances Rl and Ri are connected in series across the voltage source where Rl>Ri. The largest drop will be across (a) Rl (b) Ri (c) either Rl or Ri (d) none of them Ans: a 45. What will be energy used by the battery if the battery has to drive 6.28 x 1018 electrons with potential difference of 20 V across the terminal ? (a) 5 joules (b) 10 joules (c) 15 joules (d) 20 joules Ans: 46. A closed switch has a resistance of (a) zero (b) about 50 ohms (c) about 500 ohms (d) infinity Ans: a 47. The hot resistance of the bulb's filament is higher than its cold resistance because the temperature co-efficient of the filament is (a) zero (b) negative (c) positive (d) about 2 ohms per degree Ans: c 48. Heat in a conductor is produced on the passage of electric current due to (a) reactance (b) capacitance (c) impedance (d) resistance Ans: 49. The insulation on a current carrying conductor is provided (a) to prevent leakage of current (b) to prevent shock (c) both of above factors (d) none of above factors Ans: c 50. The thickness of insulation provided on the conductor depends on (a) the magnitude of voltage on the conductor (b) the magnitude of current flowing through it (c) both (a) and (b) (d) none of the above Ans: a 51. Which of the following quantities remain the same in all parts of a series circuit ? (a) Voltage (b) Current (c) Power (d) Resistance Ans: b 52. A 40 W bulb is connected in series with a room heater. If now 40 W bulb is replaced by 100 W bulb, the heater output will (a) decrease (b) increase (c) remain same (d) heater will burn out Ans: b 53. In an electric kettle water boils in 10 m minutes. It is required to boil the boiler in 15 minutes, using same supply mains (a) length of heating element should be decreased (b) length of heating element should be increased (c) length of heating element has no effect on heating if water (d) none of the above Ans: a 54. An electric filament bulb can be worked from (a) D.C. supply only (b) A.C. supply only (c) Battery supply only (d) All above Ans: d 55. Resistance of a tungsten lamp as applied voltage increases (a) decreases (b) increases (c) remains same (d) none of the above Ans: b 56. Electric current passing through the circuit produces (a) magnetic effect (b) luminous effect (c) thermal effect (d) chemical effect (e) all above effects Ans: c 57. Resistance of a material always decreases if (a) temperature of material is decreased (6) temperature of material is increased (c) number of free electrons available become more (d) none of the above is correct Ans: c 58. If the efficiency of a machine is to be high, what should be low ? (a) Input power (b) Losses (c) True component of power (d) kWh consumed (e) Ratio of output to input Ans: b 59. When electric current passes through a metallic conductor, its temperature rises. This is due to (a) collisions between conduction electrons and atoms (b) the release of conduction electrons from parent atoms (c) mutual collisions between metal atoms (d) mutual collisions between conducting electrons Ans: a 60. Two bulbs of 500 W and 200 W rated at 250 V will have resistance ratio as (a) 4 : 25 (b) 25 : 4 (c) 2 : 5 (d) 5 : 2 Ans: c 61. A glass rod when rubbed with silk cloth is charged because (a) it takes in proton (b) its atoms are removed (c) it gives away electrons (d) it gives away positive charge Ans: c 62. Whether circuit may be AC. or D.C. one, following is most effective in reducing the magnitude of the current. (a) Reactor (b) Capacitor (c) Inductor (d) Resistor Ans: d 63. It becomes more difficult to remove (a) any electron from the orbit (6) first electron from the orbit (c) second electron from the orbit (d) third electron from the orbit Ans: d 64. When one leg of parallel circuit is opened out the total current will (a) reduce (b) increase (c) decrease (d) become zero Ans: c 65. In a lamp load when more than one lamp are switched on the total resistance of the load (a) increases (b) decreases (c) remains same (d) none of the above Ans: b 66. Two lamps 100 W and 40 W are connected in series across 230 V (alternating). Which of the following statement is correct ? (a) 100 W lamp will glow brighter (b) 40 W lamp will glow brighter (c) Both lamps will glow equally bright (d) 40 W lamp will fuse Ans: b 67. Resistance of 220 V, 100 W lamp will be (a) 4.84 Q (b) 48.4 Q (c) 484 ft (d) 4840 Q Ans: c 68. In the case of direct current (a) magnitude and direction of current remains constant (b) magnitude and direction of current changes with time (c) magnitude of current changes with time (d) magnitude of current remains constant Ans: a 69. When electric current passes through a bucket full of water, lot of bubbling is observed. This suggests that the type of supply is (a) A.C. (b) D.C. (c) any of above two (d) none of the above Ans: b 70. Resistance of carbon filament lamp as the applied voltage increases. (a) increases (b) decreases (c) remains same (d) none of the above Ans: b 71. Bulbs in street lighting are all connected in (a) parallel (b) series (c) series-parallel (d) end-to-end Ans: a 72. For testing appliances, the wattage of test lamp should be (a) very low (b) low (c) high (d) any value Ans: c 73. Switching of a lamp in house produces noise in the radio. This is because switching operation produces (a) arcs across separating contacts (b) mechanical noise of high intensity (c) both mechanical noise and arc between contacts (d) none of the above Ans: a 74. Sparking occurs when a load is switched off because the circuit has high (a) resistance (b) inductance (c) capacitance (d) impedance Ans: b 75. Copper wire of certain length and resistance is drawn out to three times its length without change in volume, the new resistance of wire becomes (a) 1/9 times (b) 3 times (e) 9 times (d) unchanged Ans: c 76. When resistance element of a heater fuses and then we reconnect it after removing a portion of it, the power of the heater will (a) decrease (b) increase (c) remain constant (d) none of the above Ans: b 77. A field of force can exist only between (a) two molecules (b) two ions (c) two atoms (d) two metal particles Ans: b 78. A substance whose molecules consist of dissimilar atoms is called (a) semi-conductor (b) super-conducto (c) compound (d) insulator Ans: c 79. International ohm is defined in terms of the resistance of (a) a column of mercury (b) a cube of carbon (c) a cube of copper (d) the unit length of wire Ans: a 80. Three identical resistors are first connected in parallel and then in series. The resultant resistance of the first combination to the second will be (a) 9 times (b) 1/9 times (c) 1/3 times (d) 3 times Ans: b 91. Which method can be used for absolute measurement of resistances ? (a) Lorentz method (b) Releigh method (c) Ohm's law method (d) Wheatstone bridge method Ans: d 92. Three 6 ohm resistors are connected to form a triangle. What is the resistance between any two corners ? (a) 3/2 Q (b 6 Q (c) 4 Q (d) 8/3 Q Ans: c 93. Ohm's law is not applicable to (a) semi-conductors (b) D.C. circuits (c) small resistors (d) high currents Ans: a 94. Two copper conductors have equal length. The cross-sectional area of one conductor is four times that of the other. If the conductor having smaller cross-sectional area has a resistance of 40 ohms the resistance of other conductor will be (a) 160 ohms (b) 80 ohms (c) 20 ohms (d) 10 ohms Ans: d 95. A nichrome wire used as a heater coil has the resistance of 2 £2/m. For a heater of 1 kW at 200 V, the length of wire required will be (a) 80 m (b) 60 m (c) 40 m (d) 20 m Ans: a 96. Temperature co-efficient of resistance is expressed in terms of (a) ohms/°C (b) mhos/ohm°C (e) ohms/ohm°C (d) mhos/°C Ans: c 97. Which of the following materials has the least resistivity ? (a) Zinc (b) Lead (c) Mercury (d) Copper Ans: 98. When current flows through heater coil it glows but supply wiring does not glow because (a) current through supply line flows at slower speed (b) supply wiring is covered with insulation layer (c) resistance of heater coil is more than the supply wires (d) supply wires are made of superior material Ans: c 99. The condition for the validity under Ohm's law is that (a) resistance must be uniform (b) current should be proportional to the size of the resistance (c) resistance must be wire wound type (d) temperature at positive end should be more than the temperature at negative end Ans: a 100. Which of the following statement is correct ? (a) A semi-conductor is a material whose conductivity is same as between that of a conductor and an insulator (b) A semi-conductor is a material which has conductivity having average value of conductivity of metal and insulator (c) A semi-conductor is one which con¬ducts only half of the applied voltage (d) A semi-conductor is a material made of alternate layers of conducting material and insulator Ans: a 101. A rheostat differs from potentiometer in the respect that it (a) has lower wattage rating (b) has higher wattage rating (c) has large number of turns (d) offers large number of tapping Ans: b 102. The weight of an aluminium conductor as compared to a copper conductor of identical cross-section, for the same electrical resistance, is (a) 50% (b) 60% (c) 100% (d) 150% Ans: a 103. An open resistor, when checked with an ohm-meter reads (a) zero (b) infinite (c) high but within tolerance (d) low but not zero Ans: b 104. are the materials having electrical conductivity much less than most of the metals but much greater than that of typical insulators. (a) Varistors (b) Thermistor (c) Semi-conductors (d) Variable resistors Ans: c 105. All good conductors have high (a) conductance (b) resistance (c) reluctance (d) thermal conductivity Ans: a 106. Voltage dependent resistors are usually made from (a) charcoal (b) silicon carbide (c) nichrome (d) graphite Ans: c 107. Voltage dependent resistors are used (a) for inductive circuits (6) to supress surges (c) as heating elements (d) as current stabilizers Ans: b 108. The ratio of mass of proton to that of electron is nearly (a) 1840 (b) 1840 (c) 30 (d) 4 Ans: a 109. The number of electrons in the outer most orbit of carbon atom is (a) 3 (b) 4 (c) 6 (d) 7 Ans: b 110. With three resistances connected in parallel, if each dissipates 20 W the total power supplied by the voltage source equals (a) 10 W (b) 20 W (c) 40 W (d) 60 W Ans: d 111. A thermistor has (a) positive temperature coefficient (b) negative temperature coefficient (c) zero temperature coefficient (d) variable temperature coefficient Ans: c 112. If/, R and t are the current, resistance and time respectively, then according to Joule's law heat produced will be proportional to (a) I2Rt (b) I2Rf (c) I2R2t (d) I2R2t* Ans: a 113. Nichrome wire is an alloy of (a) lead and zinc (b) chromium and vanadium (c) nickel and chromium (d) copper and silver Ans: c 114. When a voltage of one volt is applied, a circuit allows one micro ampere current to flow through it. The conductance of the circuit is (a) 1 n-mho (b) 106 mho (c) 1 milli-mho (d) none of the above Ans: a 115. Which of the following can have negative temperature coefficient ? (a) Compounds of silver (6) Liquid metals (c) Metallic alloys (d) Electrolytes Ans: d 116. Conductance : mho :: (a) resistance : ohm (b) capacitance : henry (c) inductance : farad (d) lumen : steradian Ans: a 117. 1 angstrom is equal to (a) 10-8 mm (6) 10"6 cm (c) 10"10 m (d) 10~14 m Ans: c 118. One newton meter is same as (a) one watt (b) one joule (c) five joules (d) one joule second Ans: b CURRENT ELECTRICITY Objective Type Questions pdf free download :: Read the full article

0 notes

Text

We Provide Membrane Switches, Electronic Assemblies to a Variety Market

These days, you'll find establishments of which target electronic product design services and electronic product development procedures making use of up to date know-how to get merchandise improvement and practice enhancement. That they strongly use his or her clients to recognise the suitable requirements and eventually deliver benefit added in merchandise to acquire a benefit about his or her competitors.

Capacitive sensors:

In an average setup, a minimized lodging contains two firmly separated, parallel, electrically disconnected metallic surfaces, one of which is basically a stomach fit for slight flexing under weight. Capacitive sensors transducers are expertly planned adjustments of a basic, tough and on a very basic level stable device the electrical capacitor. The detecting surface is covered with a miniaturized scale porous metal terminal.

Membrane Switch Manufacturing:

Membrane switches have a huge of applications in most of the gadgets today. These switches need high rigor manufacturing, as per customized designs of the products. The market is very competing and everyone is on toes to survive with universally acceptable products. China is among the Membrane Switch Manufacturing, besides many other from the world over. The design team takes care of final finish of the product with correct matching paint, matte, glossy, or textured paint.

Membrane Keypad Manufacturer:

A membrane PC console is designed to convey excellent execution once put in the electrical or battery worked gadgets. These are tactile or non tactile switches that are generally used in a wide range of electronic hardware and day by day machines. Copper or silver is utilized in the Membrane Keypad Manufacturer by reliable membrane keypad manufacturer since it is dependable; it beyond any doubt enough conveys excellent execution when contrasted with other product offering in the business.

0 notes

Text

The contractor who cooperates with the stage lighting

The contractor who cooperates with the stage lighting should stay away from other heat sources and heat radiation sources and place them in a ventilated and dry place. Pay attention to insect control: There are many cockroaches and bed bugs in the south. If it enters the speaker, it is easy to damage the audio <a href="https://www.winpowerlights.com/product/effect-light">get more</a> paper basin, so it needs insect control.

1. Turn on the volume potentiometer of the power amplifier slowly (repeat each power amplifier), and check whether the corresponding speakers are normally amplified (at the same time, check whether each unit is normal). It should be reminded that the power amplifier is turned on to connect the speaker cable, because the speaker terminal is generally close to each other, and the speaker cable is two tightly parallel, and often the speaker wire is accidentally short-circuited when wiring, and the consequences will be The amplifier was burned quickly.

Audio equipment is composed of sound source (music player equipment, sound pickup equipment or microphone), control equipment (analog or digital mixing console), audio processor (previously used effects, equalizer, compressor, frequency divider, Distributors, delayers and other peripheral equipment now also include digital system controllers that integrate the above functions), power amplifiers (power amplifiers), and speakers. The above equipment consists of different types of wires and cables connected in series.

The sound of the engineering business with the stage lighting is a simplified everyday word and is the abbreviation of sound system. Refers to a set of equipment that can restore and play audio. With the progress of society, people yearn for more colorful life.

How to adjust the tone of the accompaniment music The accompaniment music is played according to the tone of the original singer. It cannot be adapted to the noise conditions of each singer. For example, some original singers have a higher range and some original singers sing. The sound range is relatively low. In order to allow accompaniment music to take into account the noise characteristics of each singer, the sound engineer and the tuner should have a sensitive auditory response to the singer's sound characteristics. When singing, first put the pitch control in the middle position, since it does not, it does not fall. At the beginning of a song, if the singer deserves an upward adjustment, then there is no need to adjust.

The development history of audio technology can be divided into five stages: vacuum triode, electron tube, transistor, integrated circuit and field effect tube. Transistor In 1906, the American DeForest invented the vacuum triode, which was the first in human electroacoustic technology.

Engineers who cooperate with stage lighting use acoustic computer systems to design and calculate the acoustic characteristics of sound reinforcement systems in halls, gymnasiums (fields), multi-function halls, and lecture halls, which means that it is not necessary to wait until the system is installed, commissioned, and measured. Know the design, installation and debugging results. In other words, according to the audio system and the design calculation results given in this design plan, the acoustic characteristics of the sound reinforcement system expected by the system have been clearly seen.

.Procedures for equipment debugging Each system of professional audio engineering includes more equipment types and numbers. The use methods of equipment and the working mode of the system are different, so the equipment debugging of the system is also different, but due to the engineering The types are also very different. If you want to introduce the equipment debugging methods of all types of projects one by one, it will be too long, so we will only explain the steps of equipment debugging in the general type of engineering.

In 1927, Bell Labs invented negative feedback technology, which made the development of audio technology enter a new era. The more representative such as Williamson amplifiers used the negative feedback technology successfully, which greatly reduced the distortion of the amplifier. Tubes In the 1950s, the development of tube amplifiers reached a period when tube amplifiers emerged endlessly.

In the system, there is only one pair of surround boxes, but as a long-term consideration, on this basis, distribute one or two more sets of surround speaker cables for future upgrades to or channels. When embedding the wire, whether it is digging a hole in the floor or grooving the wall, use a plastic sleeve or yellow wax tube to cover the wire, and do not directly seal it with cement.

Due to the sweet and round sound of the tube amplifier, it is still preferred by audiophiles. Transistors The emergence of transistors in the 1960s has enabled the majority of audio enthusiasts to enter a wider world of audio. The transistor amplifier has the characteristics of delicate and beautiful sound, lower distortion, wider frequency response and dynamic range.

In the early 1960s, the United States first introduced a new member of the audio technology-integrated circuits. By the early 1970s, integrated circuits were gradually recognized by the audio industry for their high quality, low price, small size, and multiple functions. . Since its development, thick film audio integrated <a href="https://www.winpowerlights.com/product/effect-light">Profile light manufacture</a> circuits and operational amplifier integrated circuits have been widely used in audio circuits. Field effect In the 1970s, Japan produced only field effect power tubes. Because the field effect power tube has the characteristics of pure tube thickness, sweet sound and dynamic range of 90dB, THD <0.01% (at 100kHz), it is quickly popular in the audio industry. Many current amplifiers use field effect transistors as the final output.

After the audio adopts digital technology, the recorded digital has a high resolution from the sampling frequency to the quantization characteristics, and there is no color jitter, resulting in a very clear image. And it can be interchanged with the host computer, which is incomparable with analog recording and playback equipment.

The general lighting cable used by the engineering company for stage lighting is both audio and video. The plugs at both <a href="https://www.winpowerlights.com/product/par-can-light">COB zoom par light supplier</a> ends of the cable are gold-plated plugs, and the surface of the conductor is coated with an anti-static protective layer. Fever line: mainly refers to the speaker transmission line with a larger cross-section and more strands. The high-quality fever wire is made of oxygen-free copper and other materials. .. Integrated power amplifier, battery, and dual speakers, the technology 'telescopically expands the resonance cavity', solves the problem of the small resonance cavity of the mini speaker, and breaks the limitations of the speaker's appearance specifications for decades.

0 notes